Gear machining is an extremely complex process, and efficient production is only possible with the right technology, and every part of the production process must be dimensioned to the highest accuracy.

The processing forms of gears include ordinary turning machining→ gear hobbing processing→ gear shaping processing→ shaving machining→ hard turning machining→ gear grinding processing→ honing processing→ drilling→ internal hole grinding→ welding → measurement, it is particularly important to configure the appropriate clamping system for this process, and then we will introduce the gear clamping system in each process.

Ⅰ. Ordinary lathe processing

In general turning, gear blanks are usually clamped on vertical or horizontal turning machines. For automatic clamping, most of them do not require an auxiliary stabilisation device on the other side of the spindle.

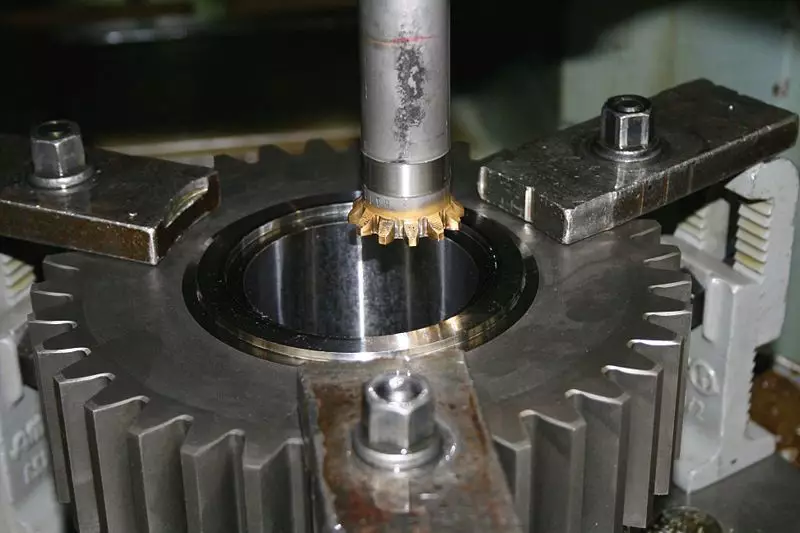

Ⅱ. Hobbing

Due to its outstanding economy, gear hobbing is a cutting process used in the production of external gears and cylindrical gears. Gear hobbing is widely used not only in the automotive industry, but also in the manufacture of large industrial transmissions, but only if it is not limited by the outer contour of the workpiece to be processed.

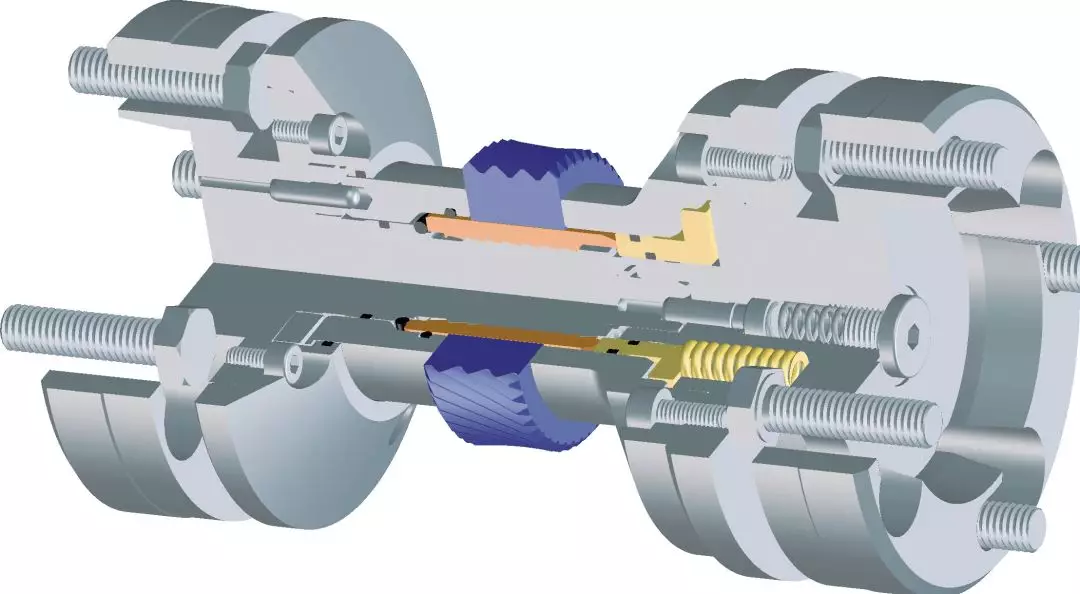

Ⅲ. Gear shaping machining

Gear shaping, a process for processing gears, is mainly used in the case that gear hobbing is not possible. This machining method is mainly suitable for the machining of internal gears of gears, as well as the machining of external gears of some gears that are disturbed by the structure.

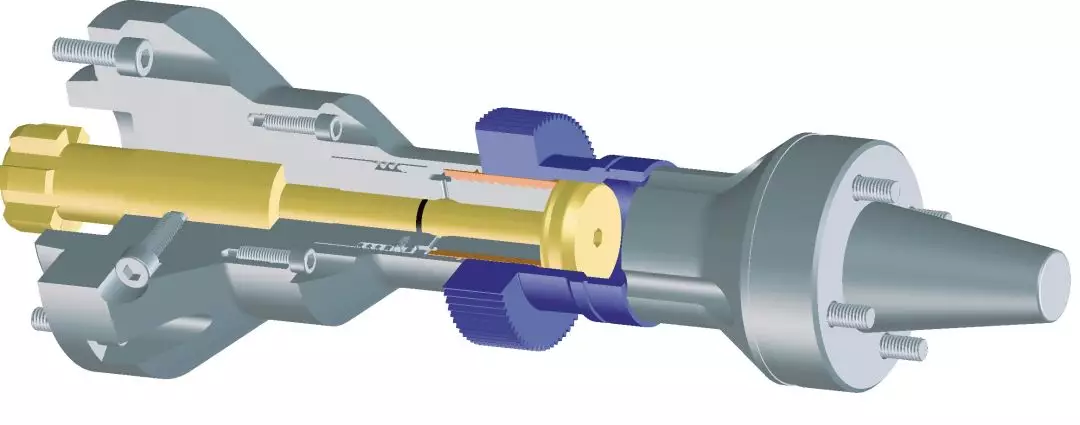

Ⅳ. Shaving machining

Shaving is a finishing process for gears that are cut with a blade corresponding to the tooth profile of the gear. This process is highly economical and therefore has been widely used in industry.

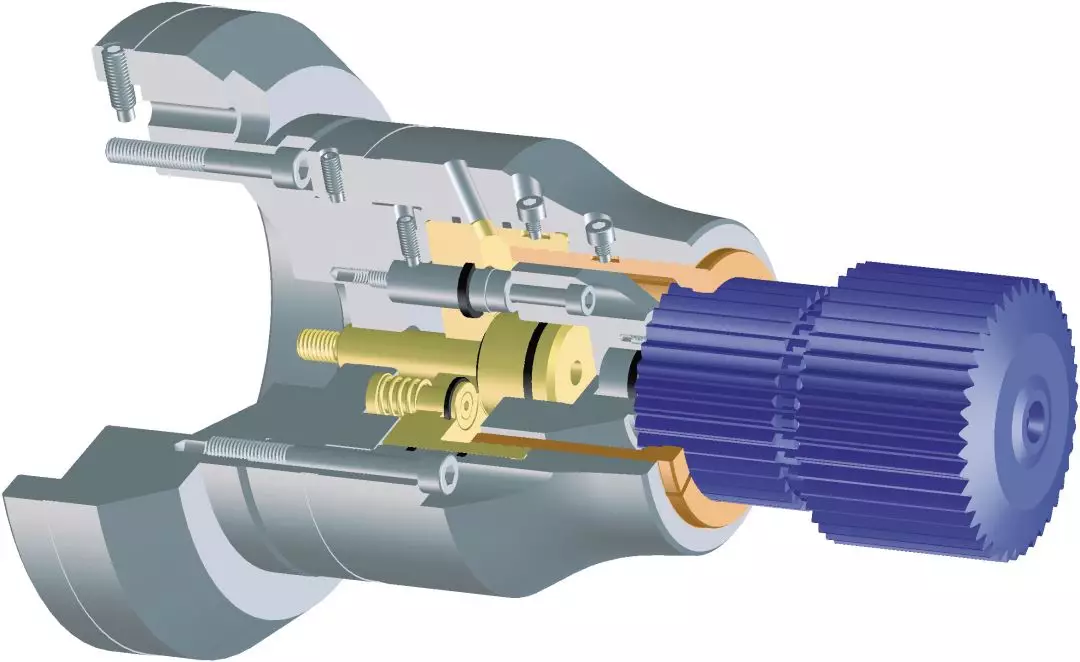

Ⅵ. Gear grinding machining

In order to successfully achieve the precision necessary in gear production today, hard finishing of the tooth flanks is in many cases essential. In mass production, it is a very cost-effective way to process. On the other hand, similar to sample machining, gear grinding shows greater flexibility when an adjustable grinding tool is used.

Ⅶ. Honing processing

Honing is the process of final finishing of hard gears using amorphous cutting angles. Honing is not only highly economical, but also gives the gears to be machined a smooth surface with low noise. Compared to grinding, honing has a very low cutting speed (0,5 to 10 m/s) and thus avoids damage to gear machining due to cutting heat. More precisely, the internal stress generated on the tooth surface to be processed has a certain positive effect on the bearing capacity of the equipment.

Ⅷ. Drilling

Drilling is a rotational cutting process. The axis of the tool and the center of the hole to be machined are exactly the same as the direction of feed of the tool in the axial direction. The spindle of the cutting motion should be consistent with the tool, regardless of the direction of the feed movement.

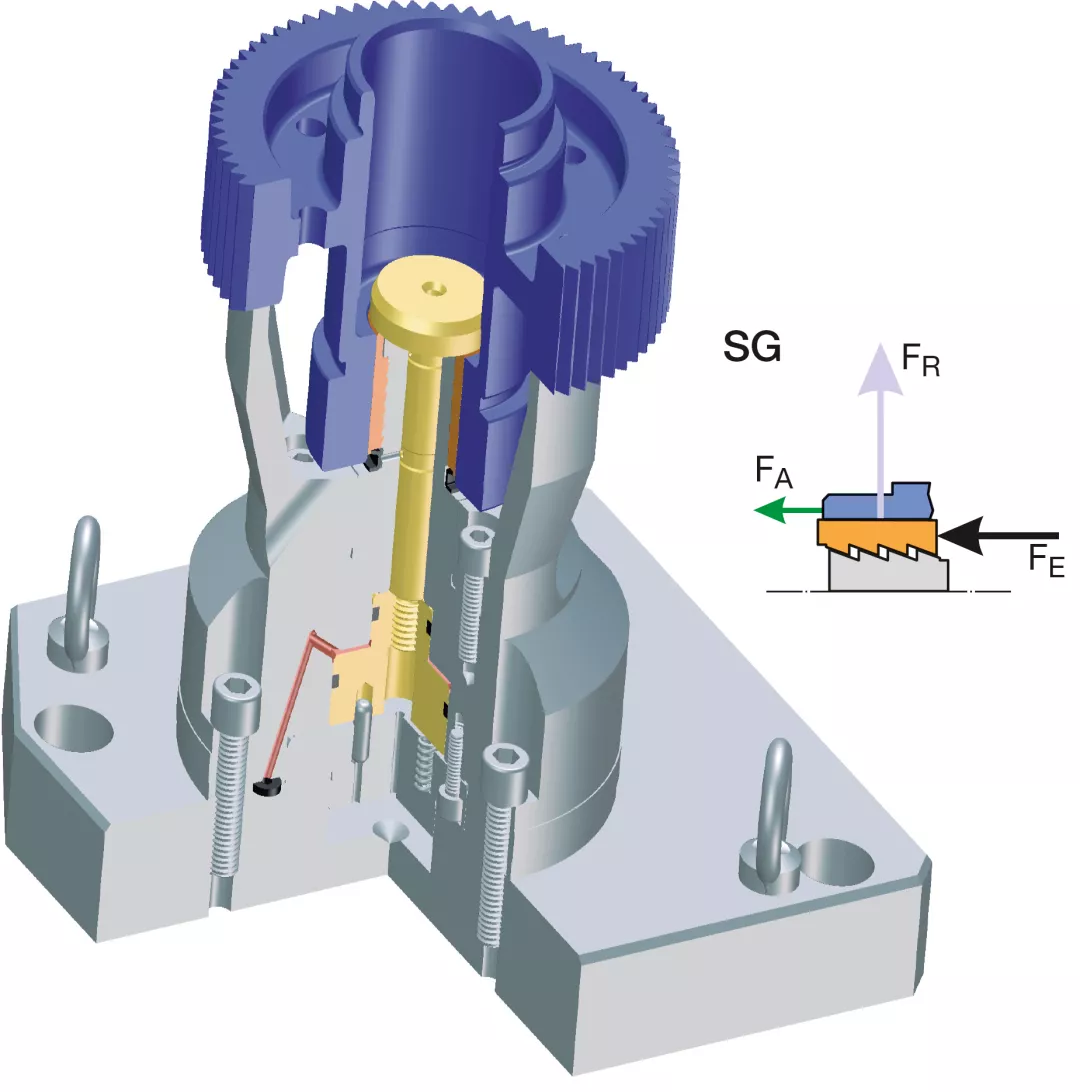

An example of drilling using the SG jig system

Ⅹ. Capacitor discharge welding

Capacitor discharge welding is a resistance welding process. Capacitive discharge welding is achieved by a very fast current increase, a fairly short welding time, and a very high welding current. Therefore, capacitor discharge welding has many advantages. In the face of increasing energy prices, the economy and efficiency of capacitor discharge welding are particularly important.

Ⅸ. Inner bore grinding.

Internal grinding is a machining process with amorphous cutting angles. Compared with other cutting processes, grinding has the advantages of high dimensional and forming accuracy, dimensional accuracy (IT 5-6), and high-quality surface accuracy (Rz = 1-3 μm) with very small chatter marks for hard metals.

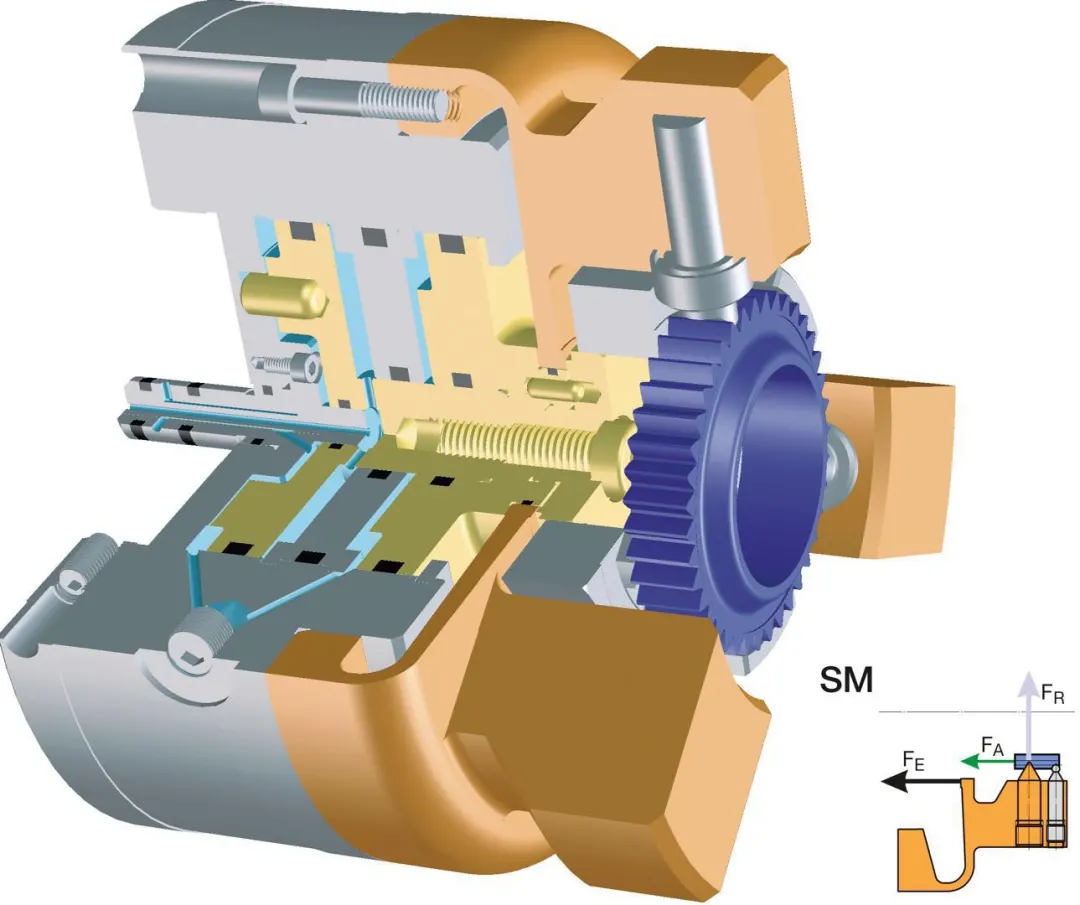

Example of internal bore grinding using the film clamping SM system

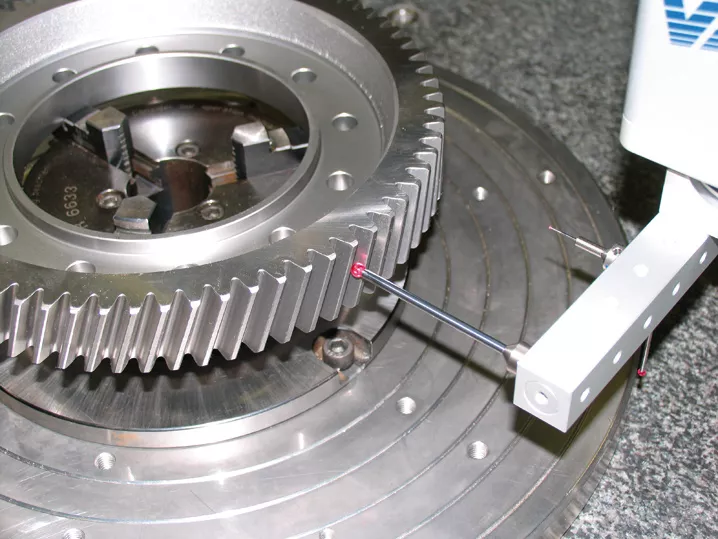

ⅩⅠ. measurement

The inspection of gears is very extensive, and it must be adjusted according to the different forms of gears. In the measurement of gears, the different important parameters of the gears are determined by the measurement of length, angle, and special gear process.

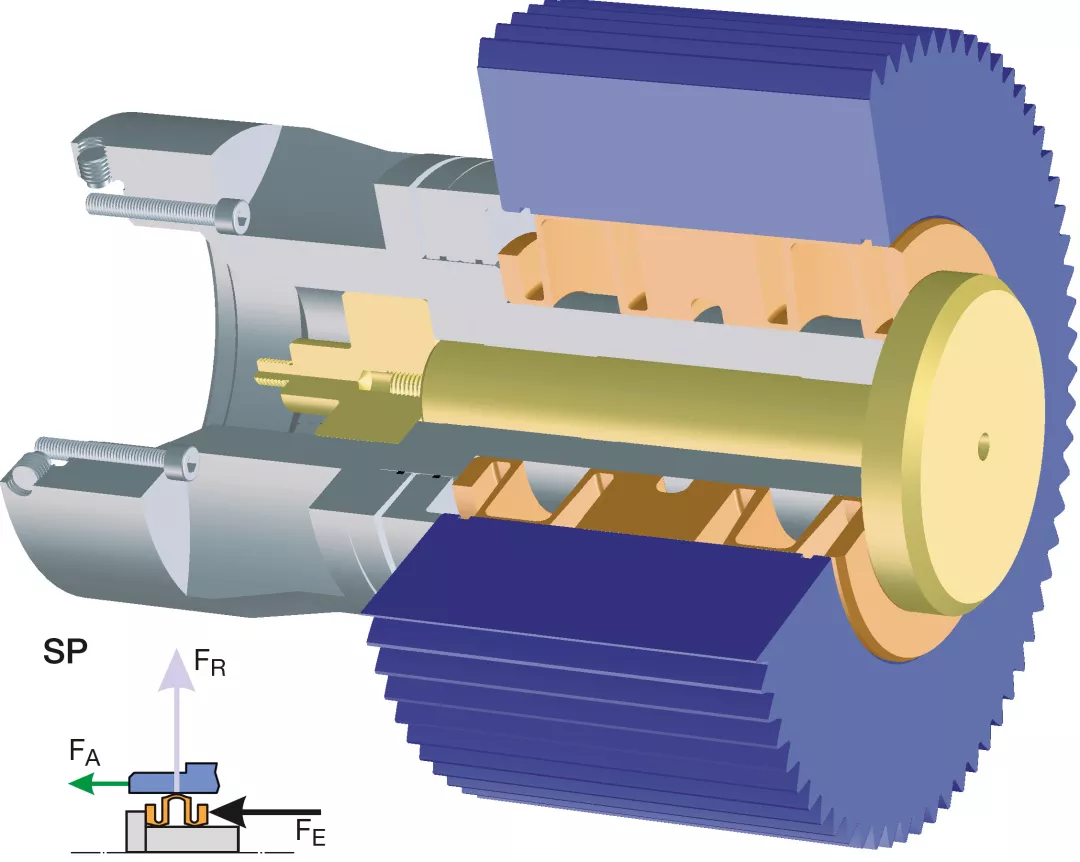

👆Example of measurement using a flanged SP fixture system