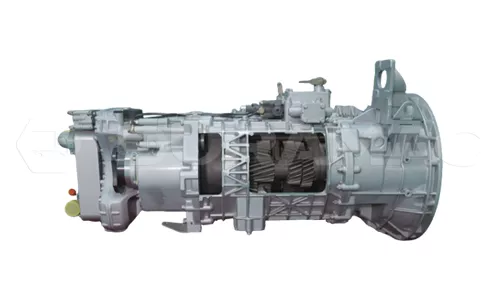

HW25712XSTL

The Datong HW25712XSTL Heavy Manual Sync Gearbox has a maximum input torque of 2500 N.m, a maximum input speed of 2600 RPM, a torque of 2500 N.m, a gear ratio range of 14.941 – 1, a weight of 325 kg (420 kg for the iron housing), an oil capacity of 11 L (11.5 L for the aluminum housing),13 L (13.5 L for the iron housing), and an overall length of 993 mm (1078 mm with a retarder). This gearbox is suitable for heavy-duty vehicle engines with a power range of 440 to 540 horsepower. (The weight does not include lubricating oil and clutch disengagement device; the length refers to the distance from the front face of the clutch stop to the output flange end; the weight in parentheses is for the iron housing; the oil capacity in parentheses is for when a power take-off is installed; the overall length in parentheses is for the version with a retarder.)

In the detailed model name, “HW” represents the brand. The number “25” indicates 1% of the torque, with the 1/10 notation used when the torque is less than three digits. The number “7” signifies the series number for the heavy-duty transmission series. “12” denotes the number of forward gears. “X” indicates helical gears, “S” stands for a double intermediate shaft, “T” signifies the presence of a synchronizer, “C” represents an overdrive gear, and “L” denotes an aluminum casing.

As part of EMAC, DuraMac provides a complete power system integrating DCEC engine, Fast-Eaton clutch, DaTong-Gear gearbox, Dongfeng-DANA axle and Komman air suspension. With the future trend of automotive electrification, Duramac is also actively developing in the field of electric vehicle power systems.

The company provides customers with full life cycle services, from design to power system supply, installation and commissioning, to after-sales service training and spare parts supply, as well as troubleshooting and overhaul technical support. This full range of services ensures that customer equipment maintains high reliability and long-term operating efficiency during use.

Advantages of HW25712XSTL Heavy Duty Manual Synchronized Transmission

-

HW25712XSTL is a full synchronizer mechanism.

-

The main box adopts a double intermediate shaft structure, a planetary mechanism for the auxiliary box, and a 6X2 combination.

-

The standard gear shift booster reduces the shift force by 50%.

-

The main box gear adopts a full helical gear design, and the noise reaches the international advanced level.

-

Forced lubrication is combined with splash lubrication.

-

A rear power take-off, a single-axis power take-off and a hydraulic retarder can be installed.

-

The overall transmission efficiency is high.

Technical Specifications

| Gearbox Model: | HW25712XSTL |

| Oil Capacity(PTO): | 9.5 L(10.5 L) |

| Maximum Input Speed: | 2600 RPM |

| Maximum Input Torque: | 2500 N.m |

| Torque: | 2500 N.m |

| Total Length: | 993 mm |

| Gear Ratio Range: | 14.941 – 1 |

| Dry Weight: | 325 kg (420 kg) |

| Lead Time: | 15 – 30 Working Days |

| Payment Terms: | T/T ,L/C |

HW25712XSTL

The DaTong-Gear HW25712XSTL Heavy Manual Sync Gearbox features a total length of 993 mm (1078 mm), weighs 325 kg (420 kg), and has an oil capacity of 11 L (11.5 L) for the aluminum casing and 13 L (13.5 L) for the iron casing.

DuraMac

DCEC ISL8.9 series automotive engine is four-strokes engine with 102 mm bore and 120 mm stroke, Equipped with Bosch (or BYC or Weifu) pump. engine comes with turbocharger and Air- Air intercooler. The prime power range is from 269 HP to 394 HP.

Fast Gear

The F6A Series Automated Transmission uses the FAST automatic transmission, has six front gears, the transmission ratio step arrangement is reasonable, has very outstanding fuel economy. Adopt hydraulic automatic transmission. The F6A Series Automated Transmission has six gears, each with a different reduction ratio.

EV Truck

Electric wheel dump trucks use electricity as a power source, completely abandoning traditional fuel engines. This change enables the vehicle to achieve true “zero emissions” during operation, without the emission of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter in the exhaust gas, greatly reducing the pollution to the atmospheric environment.

DANA Axle

Applying the advanced technology of DANA with high efficiency, fuel economy, strong load torque, low noise,high reliability, lower procurement cost, low repair cost and lower maintenance cost.

Datong Gear

The Datong HW25712XSJ Heavy Manual No-Sync Gearbox has a torque of 2500 N.m, a gear ratio range of 14.941-1, an oil capacity of 13 L (13.5 L when equipped with a power take-off), an overall length of 993 mm, and a weight of 428 kg.

Crane Trucks

The DFZ5258JSQSZ6D truck crane is a powerful and versatile vehicle designed for efficient lifting and transportation tasks. Equipped with a YCS06300-61 engine and a Shaanxi Auto Fast gear : 10JS120TA high-low gear with synchronizer、PTO gearbox, it provides strong and stable power for demanding operations.

Gearbox Model |

Torque |

Gear Ratio Range |

Total Length |

Oil Capacity(PTO) |

|

| HW25712XSTL | 2500 N.m | 14.941 – 1 | 993 mm | 11 L(11.5 L)Aluminum casing 13 L(13.5 L)Iron casing | |

| HW25712XSTCL | 2500 N.m | 11.697 – 0.783 | 993 mm | 11 L(11.5 L)Aluminum casing 13 L(13.5 L)Iron casing | |

| ——END—— | |||||

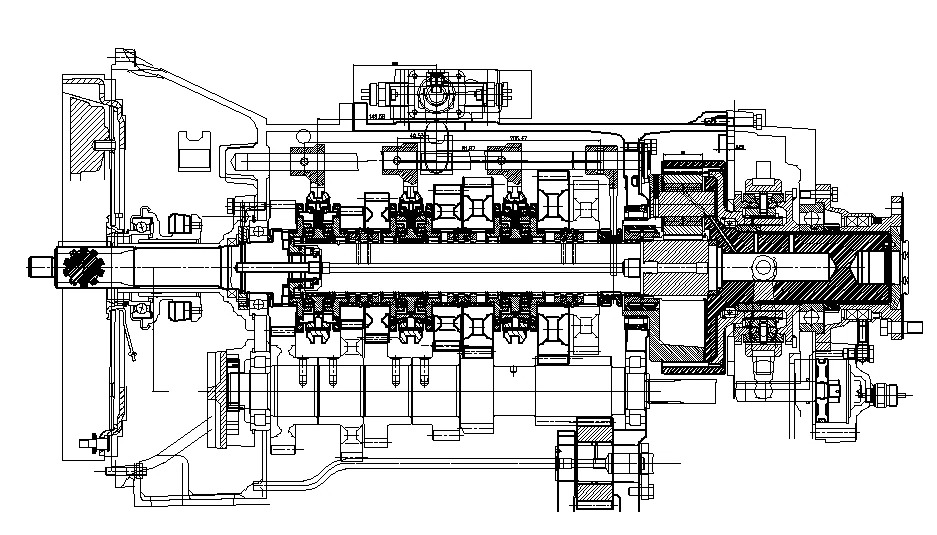

HW25712XSTL Gearbox Main Performance Parameters

| Product Model | All Gear Positions Speed Ratio Table | |||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | R1 | R2 | |

| HW13709XSTC2 | 14.941 | 11.611 | 8.700 | 6.762 | 5.515 | 4.318 | 3.460 | 2.689 | 2.081 | 1.618 | 1.277 | 1 | 3.045 | 13.148 |

| Maximum Input Torque | 2500 N.m | Maximum Input Speed | 2600 RPM | |||||||||||

| Dry Weight | 325 kg (420 kg) | Oil Capacity(PTO) | 11 L(11.5 L)Aluminum casing 13 L(13.5 L)Iron casing |

|||||||||||

| Gear Ratio Range | 14.941 – 1 | Torque | 2500 N.m | |||||||||||

| Total Length | 993 mm (1078 mm) | |||||||||||||

|

Note:

|

||||||||||||||

Our products are designed and manufactured in strict accordance with industry standards, ensuring the precision of every part’s dimensions to meet the high standards of compatibility, performance, and safety required by our customers. The accuracy of dimensions is crucial for the correct installation and optimal operation of the products; any deviation may lead to installation issues, performance degradation, or even safety hazards. Therefore, we strongly recommend that customers carefully refer to the technical drawings and specifications we provide when purchasing, and select the most suitable product model based on their specific needs and procurement standards. We are committed to delivering high-quality products and exceptional customer service to ensure customer satisfaction and the smooth progress of projects.

The following is the numbering rules of Datong HW25712XSTL transmission.The gearbox’s main box incorporates dual intermediate shaft helical gears and a fully synchronized structure, while the auxiliary box features a planetary reduction mechanism. This design enhances load-bearing capacity, ensures structural reliability, and provides more agile and effortless operation.

Use, Maintenance, and Precautions for HW25712XSTL Transmission

Requirements for use

Operating the transmission properly and reasonably, and conducting regular maintenance are crucial for ensuring the safe and reliable operation of the vehicle and for extending the lifespan of the transmission. Please follow the usage requirements outlined below:

1. Lubricating oil brand

The transmission should be filled with 85W/90 (GL-5 grade) vehicle gear oil.

2.Correct oil level

Make sure the oil level is flush with the oil level observation port. Check the oil level through the oil level observation port on the side of the housing. Fill the oil until it overflows from the orifice. The oil filling volume for aluminum case transmission is about 11L (11.5L when a power take-off is installed); the oil filling volume for iron case transmission is about 13L (13.5L when a power take-off is installed).

3.Oil level check

The oil level should be checked regularly. When checking the oil level, the vehicle should be parked on a level surface. Due to the expansion of hot oil, in order to prevent inaccurate measurement, the vehicle cannot be checked immediately after driving. It can only be checked when the oil level is stable and the oil temperature is close to normal temperature.

4. Replenish the lubricant

In order to prevent chemical reactions between different types of lubricating oil, the lubricating oil should be of the same type as the original when replenishing the lubricating oil.

5. Oil Change Period

When changing the lubricating oil in the transmission, first drain the original lubricating oil in the transmission and clean the oil filter.

When a new transmission travels 2,000 to 5,000 kilometers, the lubricating oil must be replaced and the filter screen of the oil filter device must be cleaned. The lubricating oil level and leakage should be checked every 10,000 kilometers, and refilled at any time.

Long-distance transport vehicles: 80,000 km or 12 months for high-speed operation; 40,000 km or 6 months for normal operation; 20,000 km or 6 months for heavy-duty operation, whichever comes first, replace the lubricating oil and the filter screen of the oil filter device.

Municipal vehicles, urban construction engineering vehicles, transport dump trucks, mixer trucks: 40,000 kilometers (20,000 kilometers under severe working conditions) or 6 months, whichever comes first.

Mining construction site vehicle: 10,000 kilometers or 2 months (or the main engine works for 500 hours), whichever comes first.

Note: Severe working conditions refer to the situation where the vehicle is seriously overloaded, the road conditions are poor, and there is a lot of dust.

For details on retarder oil usage and oil change cycle, please refer to Zhongzhongji Zhongbianhanzi [2015] No. 236 “Notice on Changes in Voith Retarder Oil Usage and Recommended Oil Change Cycle”.

6. Operating Temperature

The maximum temperature of the transmission during continuous operation must not exceed 120°C and the minimum temperature must not be lower than -40°C. If the operating temperature exceeds 120°C, the lubricating oil will decompose and shorten the service life of the transmission.

Any of the following conditions can cause the transmission’s operating temperature to exceed 120°C.

- Operating continuously at a driving speed of less than 32 km/h.

- High engine speed.

- High ambient temperature.

- Vortex Surrounding transmission.

- The exhaust system is too close to the transmission.

- High-power overspeed operation.

7. Working Tilt Angle

When the operating inclination angle of the transmission exceeds 15°, lubrication may be insufficient (the operating inclination angle is equal to the mounting angle of the transmission on the chassis plus the ramp angle).

8. Drag or slide

Never depress the clutch pedal to allow the vehicle to coast in neutral.

When the vehicle needs to be towed, the half shaft can be pulled out or the transmission shaft can be disengaged, or the driving wheels can be lifted off the ground for towing.

9. When the vehicle speed exceeds 26 km/h, it is strictly forbidden to shift the transmission from high gear to low gear.

10. Insert and drop switching operation mode

When switching between high and low gears, first switch the switch on the shift handle. For example, when shifting from 1L to 1H, turn the switch on the handle from L to H, then step on the clutch pedal. When the clutch is completely disengaged, release the pedal, and the high and low gear switching is completed. If you step on the clutch pedal first, then release it, and then switch the switch on the handle, the gear will not switch.

Matters needing attention

1. When shifting gears, the clutch must be completely disengaged and the gear lever should be in place.

2. The shift handle switch valve has two positions: high gear and low gear. When parking, the switch valve should be placed in the neutral position in the low gear area.

3. When the vehicle is in low gear or reverse gear, the vehicle should be stopped first and then the gear should be shifted to avoid damaging the internal parts of the transmission. When shifting in reverse gear, a larger shift force is required to overcome the resistance of the reverse gear lock, and the shift force is also larger than that of the forward gear.

4. When the vehicle is in low gear or reverse gear, the vehicle should be stopped first and then the gear should be shifted to avoid damaging the internal parts of the transmission. When shifting in reverse gear, a larger shift force is required to overcome the resistance of the reverse gear lock, and the shift force is also larger than that of the forward gear.

5. When the vehicle is going downhill, it is forbidden to change the high and low gear zones.

6. Depending on the road conditions, start in 1st or 2nd gear.

7. Before starting the vehicle, the brakes should be released first. After the brake valve of a vehicle using air-off braking is turned on, the air pressure must rise to the pressure required for release before the gear can be engaged and started.

8. If unusual noises are heard from the transmission while in use, or if the operation feels significantly heavier or other abnormal phenomena are observed, one should immediately stop the vehicle and check it. Resume driving only after the issue has been resolved.

9. The transmission is equipped with a main and auxiliary box interlocking mechanism. When the auxiliary box is not shifted in place, the main box shift is locked. If you cannot engage the gear when shifting, the main and auxiliary box interlock may be at work. Please First check the range block cylinder and its air path to ensure that the auxiliary box is in gear

10. The transmission within the “three guarantees” (warranty) period must not be disassembled or assembled without authorization.

Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.

Engine Sale Manual

Installation Drawing

Installation Manual

Operation Manual

Parts Catalogue