HW95510ACL

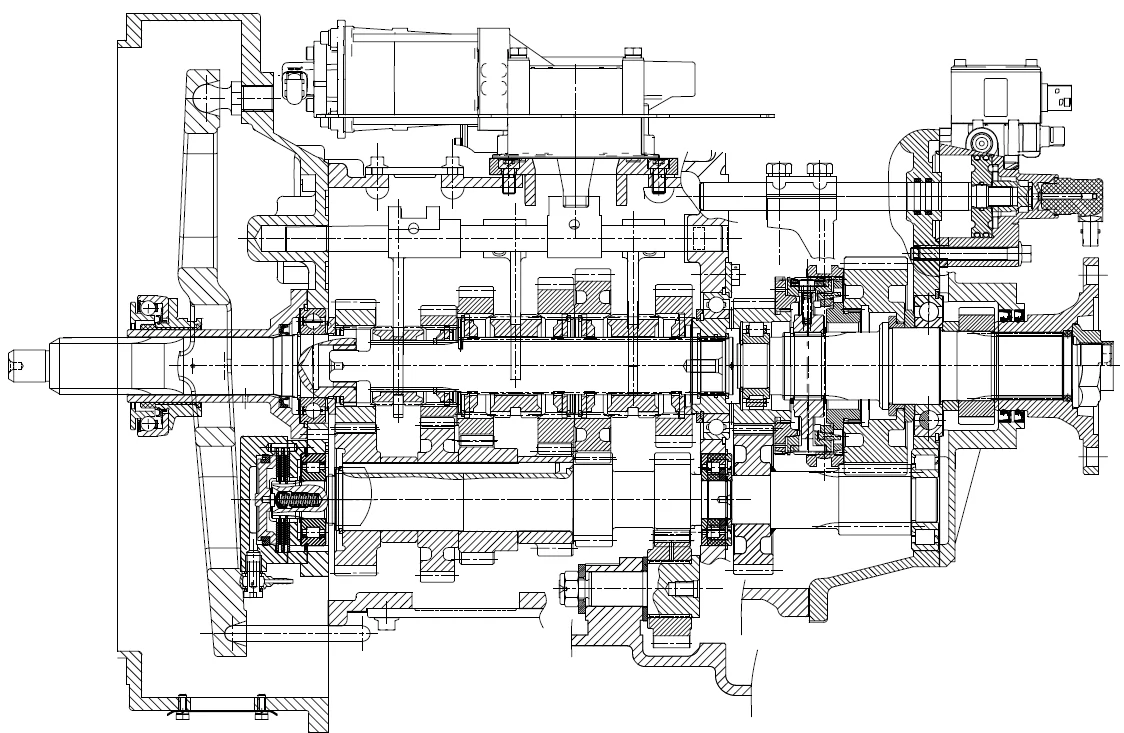

The Datong-Gear HW95510ACL AMT Hybrid Gearbox features an input maximum torque of 950 N.m, an input maximum speed of 3200 RPM, and a gear ratio range from 9.06 to 0.78. The aluminum casing weighs 148 kg, Overall dimensions 762.2 mm * 464.4 mm * 550 mm. It uses SAE 80W-90 long-life gear oil (compliant with J2360) with an oil capacity of 6 liters. The operating air pressure is between 6.5 and 8 Bar, and the operating voltage is 24V DC. This gearbox is suitable for light to medium-duty vehicles with a power range of 220 to 300 horsepower. (The weight does not include the lubricating oil; the length refers to the distance from the front face of the clutch to the output flange.)

In the detailed model name, “HW” represents the brand. The number “95” indicates 10% of the torque, with the 1% notation used when the torque exceeds three digits. The number “5” signifies the series number for the light to medium-duty transmission series. “10” denotes the number of forward gears. “A” stands for AMT (Automated Manual Transmission). “C” represents an overdrive gear, and “L” indicates an aluminum casing.

As part of EMAC, DuraMac provides a complete power system integrating DCEC engine, Fast-Eaton clutch, DaTong-Gear gearbox, Dongfeng-DANA axle and Komman air suspension. With the future trend of automotive electrification, Duramac is also actively developing in the field of electric vehicle power systems.

The company provides customers with full life cycle services, from design to power system supply, installation and commissioning, to after-sales service training and spare parts supply, as well as troubleshooting and overhaul technical support. This full range of services ensures that customer equipment maintains high reliability and long-term operating efficiency during use.

Advantages of HW95510ACL AMT and Hybrid Transmission

-

Both the main and auxiliary boxes have a double intermediate shaft structure, a fine and high gear design, and low noise.

-

The housing is a cylindrical structure, an all-aluminum shell, and is light in weight.

-

Adopting WABCO software platform and actuators, the software and hardware are highly mature.

-

Can match AMT2.0 traditional shift handle, hand-held gear shifting, and worry-free shifting, with a variety of operating methods for users to choose.

-

Can be equipped with a side power take-off; optional tandem hydraulic retarder.

-

Even step difference, sufficient power, low fuel consumption, compared with manual transmission, it can save 3%-5% fuel.

-

Can use long-term lubricating oil, the first and fixed warranty is 100,000 kilometers.

Technical Specifications

| Gearbox Model: | HW95510ACL |

| Oil Capacity: | 6 L |

| Maximum Input Speed: | 3200 RPM |

| Maximum Input Torque: | 950 N.m |

| Overall Dimensions(L * W * H): | 762.2 mm * 464.4 mm * 550 mm |

| Gear Ratio Range: | 9.06 – 0.78 |

| Working Air Pressure: | 6.5 ~ 8 Bar |

| Working Voltage: | 24V DC |

| Dry Weight: | 148 kg |

| Lead Time: | 15 – 30 Working Days |

| Payment Terms: | T/T ,L/C |

Gearbox Model |

Maximum Input Torque |

Gear Ratio Range |

Working Air Pressure |

Working Voltage |

|

| HW95510ACL | 950 N.m | 9.06 – 0.78 | 6.5~8 Bar | 24V DC | |

| ——END—— | |||||

HW95510ACL Gearbox Main Performance Parameters

| Product Model | All Gear Positions Speed Ratio Table |

|||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | R1 | R2 | |

| HW95510ACL | 9.06 | 6.78 | 5.1 | 3.91 | 3.05 | 2.32 | 1.73 | 1.3 | 1 | 0.78 | 7.55 | 1.93 |

| Maximum Input Torque | 950 N.m | Maximum Input Speed | 3200 RPM | |||||||||

| Dry Weight | Aluminum case weight 148 kg | Lubricating Oil | SAE 80W-90 long-life gear oil (compliant with J2360), refueling volume 6L | |||||||||

| Gear Ratio Range | 9.06 – 0.78 | Input Sensor | Number of teeth: 30, Position: Main gearbox intermediate shaft third gear | |||||||||

| Overall Dimensions(L * W * H) | 736.7 mm * 451 mm * 432.3 mm | Output sensor | Number of teeth: 16 | |||||||||

| Working air pressure | 6.5 ~ 8 Bar | Operating voltage | 24V DC | |||||||||

Note:

|

||||||||||||

Our products are designed and manufactured in strict accordance with industry standards, ensuring the precision of every part’s dimensions to meet the high standards of compatibility, performance, and safety required by our customers. The accuracy of dimensions is crucial for the correct installation and optimal operation of the products; any deviation may lead to installation issues, performance degradation, or even safety hazards. Therefore, we strongly recommend that customers carefully refer to the technical drawings and specifications we provide when purchasing, and select the most suitable product model based on their specific needs and procurement standards. We are committed to delivering high-quality products and exceptional customer service to ensure customer satisfaction and the smooth progress of projects.

The following is the numbering rules of Datong HW95510ACL transmission.The auxiliary gearbox of this transmission adopts a dual intermediate shaft fully synchronized structure, which has strong load-bearing capacity. This transmission is characterized by its reliable structure, flexible and easy operation, and other advantages.

Use, Maintenance, and Precautions for HW95510ACL Transmission

Requirements for use

Correct and reasonable operation and use of the transmission and regular maintenance are very important to ensure safe and reliable driving of the vehicle and extend the life of the transmission. Please follow the following usage requirements:

1. Lubricating oil brand

The gearbox is filled with long-lasting oil SAE 80W/90 (in accordance with J2360).

2. Correct oil level

Make sure the oil level is flush with the bottom edge of the oil level observation port. Check the oil level through the oil level observation port on the side of the housing. Fill the oil until it overflows from the orifice.

3. Oil level check

The oil level should be checked regularly. When checking the oil level, the vehicle should be parked on a level surface. Due to the volume expansion of hot oil, in order to prevent inaccurate measurements, the vehicle cannot be inspected immediately after driving. It can only be carried out when the oil level is stable and the oil temperature is close to normal temperature.

4. Replenish lubricating oil

To prevent chemical reactions between different types of lubricating oil, it is essential to replenish the lubricating oil with the same model as the original when topping up.

5. Oil change cycle

When changing the lubricating oil in the gearbox, first drain the original lubricating oil in the gearbox.

The lubricating oil of a new gearbox must be replaced when driving 2,000 to 5,000 kilometers. The oil level and leakage of the lubricating oil should be checked every 10,000 kilometers and replenished at any time.

The maintenance is carried out according to the following oil change cycle:

Long-distance transport vehicles: Lubricant replacement after 80,000 kilometers or 12 months, whichever comes first, in high-speed conditions.

Municipal vehicles, urban construction engineering vehicles, transport dump trucks, mixer trucks: 40,000 kilometers (20,000 kilometers under severe working conditions) or 6 months, whichever comes first.

Note: Severe working conditions refer to the situation where the vehicle is seriously overloaded, the road conditions are poor and there is a lot of dust.

6. Operating Temperature

The maximum temperature of the transmission during continuous operation must not exceed 120°C and the minimum temperature must not be lower than -40°C. If the operating temperature exceeds 120°C, the lubricating oil will decompose and shorten the service life of the transmission.

Any of the following conditions can cause the transmission’s operating temperature to exceed 120°C.

- Operating continuously at a driving speed of less than 32 km/h.

- High engine speed.

- High ambient temperature.

- Vortex Surrounding transmission.

- The exhaust system is too close to the transmission.

- High-power overspeed operation.

7. Working Tilt Angle

When the operating inclination angle of the transmission exceeds 15°, lubrication may be insufficient (the operating inclination angle is equal to the mounting angle of the transmission on the chassis plus the ramp angle).

8. Drag or slide

When the vehicle needs to be towed, the half shaft can be pulled out or the transmission shaft can be disengaged, or the driving wheels can be lifted off the ground for towing.

9. It is necessary to regularly check the wiring harness interface, oil pipe and air pipe interface, and there must be no leakage, looseness, etc.

10. The gearboxes within the “Three Guarantees” period are not allowed to be disassembled and assembled without permission.

Matters needing attention

1. It must be ensured that the air pressure in the gas line is not less than 0.65MPa (6.5bar) to ensure the normal use of various functions of the AMT system.

2. If the vehicle’s air circuit is leaking, the residual air pressure in the air circuit cannot guarantee the clutch action and correct gear shifting for a long time. The driver must quickly move the vehicle to a safe area for inspection (Do not attempt to start the vehicle again).

3. If a transmission alarm or failure symbol appears on the instrument display, please do not drive the car until the maintenance engineer has successfully rectified the fault.

4. Before turning off the engine and parking, ensure that the gear is shifted to neutral and the handbrake is applied to prevent the vehicle from rolling and to ensure the engine starts normally.

5. After the vehicle is parked and the engine is turned off, if the engine cannot be started due to the transmission being in gear and the whole vehicle’s air pressure being insufficient to return the transmission to the neutral position, you can use an inflation hose or air pump to inflate the clutch booster cylinder. After the clutch is disengaged, the engine can be started normally.

6. If the current engine speed is lower than the engine’s idle speed, the clutch may be automatically disengaged. Therefore, the engine speed is never allowed to fall below idle speed.

7. It is recommended to use the manual function under special working conditions.

Note: All Above Data are Just for Reference, All Data Might Change Without Notices or Updates, Please Contact Our Sales Team to Confirm All Details Via WhatsApp or Email.

Engine Sale Manual

Installation Drawing

Installation Manual

Operation Manual

Parts Catalogue