The history of planetary gearboxes can be traced back to the early 18th century, when Scottish engineer William ·Murdoch invented this gear structure to improve the power transmission ratio of steam engines, which was used to lower groundwater levels in tin mines. Planetary gears still play a crucial role in modern drive technology today. Whether in bicycles, automobiles, commercial vehicles, or electric motors in mechanical engineering, there are a wide range of applications. Its compact structure and ability to create a forced-lock connection between the various drives and generators in the vehicle make it an ideal device for transmitting torque in hybrid and all-electric vehicles. In recent years, the quality standards of internal and external rings have become more and more demanding, and manufacturers are facing very high challenges in their production capacity. Based on the PITTLER SkiveLine skiving machine, PITTLER T&S (PITTLER Machine Tools) offers a trend-setting, end-to-end full-sequence machining solution for the pre-hot machining of ring parts, supporting high-volume orders from Tier 1 suppliers in the automotive component sector.

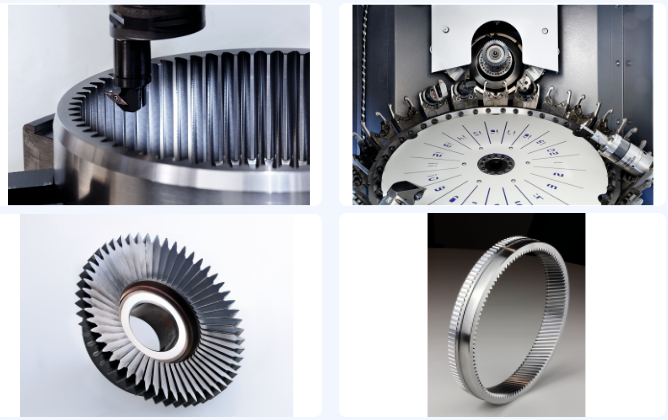

Ring gears and planetary gear sets in general are required to be compact, light, strong and precise. In view of these requirements, the most sensitive parts must be manufactured with the highest precision and best cost-effectiveness. Both attributes are due to the thin-walled structure of the components and the range of processes required to produce grooves, oil holes or lubrication pockets on the inner and outer diameters, which are particularly demanding processing requirements. A leading global manufacturer of commercial vehicles contacted PITTLER T&S, a member of the DVS Group, with the aim of making the existing production line more efficient and economical. Particular emphasis was placed on the need to significantly reduce the previously large number of six process steps. Six process steps were reduced to two.

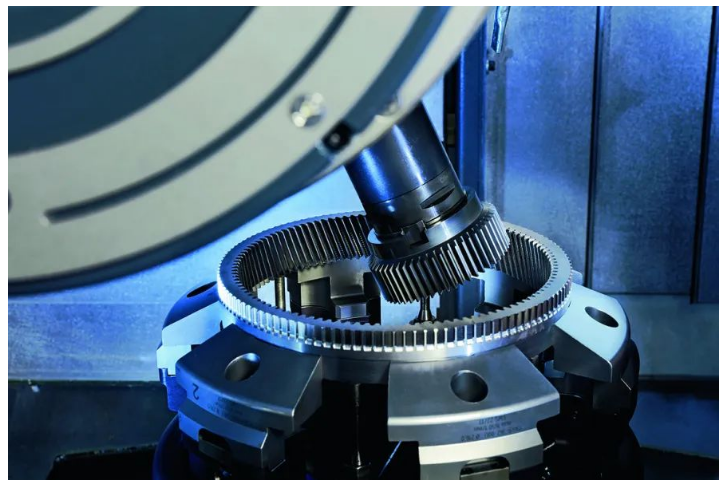

After several successful trials, the experienced manufacturer of turning and gear machines in Diezenbach, Hesse, has been convinced by its customers for its optimized multi-tasking processes at its production site. Based on its SkiveLine skiving machine, PITTLER has developed an end-to-end production process that covers all processes from turning to gear machining prior to heat treatment, including PITTLER SKIVING skiving skiving technology.

The OP10 includes turning, gear machining and drilling processes on the outer diameter of the workpiece. The OP20 integrates PITTLER SKIVING gear skiving technology for internal gear machining, as well as turning of all internal cavity steps and grooves. Therefore, after the subsequent nitriding treatment, the workpiece can be directly used for assembly. If you have two SkiveLine gear skiving machines with automatic loading and unloading devices, you can achieve full sequence processing of the entire part. Compared with the processing technology of a single machine tool, multiple single-machine process steps can be integrated into two sequences, optimizing the cycle structure and improving the overall production efficiency. Another advantage of this process is that although the actual cutting time is not much different, the auxiliary time is greatly shortened.

Clamping system solutions

The right clamping design is crucial for high-precision machining. This problem was solved in a joint effort between DVS SPANNTECHNIK, the clamping business unit of the DVS Group, and PITTLER. “The results of the first test machining have already shown that the wall thickness of the workpiece is of great significance, because the wall thickness of the workpiece will become very thin after machining,” said Mr. Omar Sharif, Product Manager for Skiving Technology at PITTLER. “Conventional clamping methods cause excessive clamping deformation of the workpiece during machining. The radial run-out in this case makes it almost impossible to achieve the specified final accuracy requirements,” he concluded. Instead, in the first operation (OP10), the workpiece is clamped on a fixed spindle. The spindle first radially centers the workpiece from the inside and then fixes the workpiece with an axial force of 10,000 N using three axial pulling claws. This special clamping concept helps to reduce radial deformation during clamping to only 2μm. The second operation also produces similarly successful results. After the automation cell feeds the workpiece into the machining area in the correct orientation, a six-jaw film chuck designed by DVS SPANNTECHNIK clamps the workpiece at its outer diameter.

The clamping force acts on the workpiece through two points on each jaw, reducing the clamping deformation to 4 μm. In addition to this, taking into account the stresses released by the material during machining as well as the tool and machining errors, the radial run-out error of the internal teeth can be reduced to just 40 μm thanks to the innovative clamping system.

William Murdoch may have dreamed of such a precise and efficient solution for the production of planetary gear set components. Now, however, the commercial vehicle manufacturer has benefited from the new line: fewer machine benches, fewer operating steps, fewer operators, and significantly more efficiency and precision in the processing of internal rings.